Location: Home >> Detail

TOTAL VIEWS

J Sustain Res. 2024;6(3):e240038. https://doi.org/10.20900/jsr20240038

1 Arabian Peninsula Regional Program, International Center for Agricultural Research in the Dry Areas—ICARDA, Dubai 13979, United Arab Emirates

2 Horticulture Research Section, Directorate General of Agriculture and Livestock Research, Ministry of Agriculture, Fisheries and Water Resources, Muscat 121, Oman

3 Agricultural Research Section, Agriculture Development & Health, Ministry of Climate Change and Environment, Dubai 1509, United Arab Emirates

4 International Center for Agricultural Research in the Dry Areas—ICARDA, Rabat, 10010, Morocco

5 International Center for Agricultural Research in the Dry Areas—ICARDA, Tunis 2049, Tunisia

* Correspondence: Arash Nejatian.

In most desert ecosystems of the Arabian Peninsula Region (APRP), vegetable production is carried out under controlled environment structures covered with polycarbonate sheets and inbuilt evaporative cooling systems. The areas with mild winter, polycarbonate cover and evaporative cooling are not required. The former can be replaced by insect proof net and the latter with a root zone cooling system to maintain the root zone area temperature at 25 ℃ at early summer. The aim of the study was to test a combination of five technologies, namely insect proof net, hydroponic closed system, root zone cooling (RZC) through fertigation chilling, ultra-low-pressure drippers, and low establishment cost of solar energy and test the potential of the system to extend the production period into the summer. The trials have been carried out in the Sultanate of Oman and UAE simultaneously on Cucumber. The results showed that by replacing the polycarbonate cover with an insect prove net and the evaporative cooling with solar energy powered ultra-low-pressure drippers, the water and energy consumption has been reduced by 85% and 90%, respectively, production period was extended to early August. Despite the implementation of these advanced techniques aimed at reducing production costs, the yield and profitability of cucumber cultivation remained limited specialty in UAE. However, the research showcased the promising potential of RZC powered by solar energy in extending the production period of net houses throughout the hot summer months.

Open field production of annual crops is constrained by the inherent hyper aridity in desert ecosystems. Thus, food production under controlled environment agriculture (CEA) constitutes a main pillar of food production in desert ecosystems. According to a report by GLOBE NEWSWIRE—The Global Controlled Environment Agriculture Market size was USD 74.4 Billion in 2022. It is expected to grow at a Compound Annual Growth Rate of 18.13% and is predicted to reach a value of USD 377.6 Billion by 2032. The report cites the increasing demand for locally grown, fresh produce, as well as the need to optimize resource use and reduce environmental impact, as the primary drivers of this growth [1].

CEA refers to the practice of growing crops in a controlled environment that uses technologies such as artificial lighting, temperature control, and cooling systems. While CEA can offer several advantages, including year-round crop production and higher yields, the use of high water and energy consumption evaporative cooling systems can compromise its sustainability.

Evaporative cooling systems are one of the most used cooling systems in CEA facilities. These systems work by passing warm air through a wet pad, which cools the air through evaporation. However, this process requires a constant supply of water to keep the pads wet, which can result in high water consumption. A study published in Agricultural Water Management Journal in 2021 found that evaporative cooling would consume 4 times more water than actual water used for crop production [2]. In Kuwait, Albaho and Al-Mazidi indicated that the water used for cooling was about 2.2 times more than the water used for actual production per unit area [3].

Moreover, the energy consumption of an evaporative cooling system can be significant, which can increase the operational costs of CEA facilities. A study published in the journal Sustainability in 2021 found that the energy consumption of an evaporative cooling system was the highest among all the subsystems in a CEA facility, accounting for 35% of the total energy consumption [4]. In addition, the use of high water and energy consumption evaporative cooling systems can have negative environmental impacts. The energy consumed by these systems contributes to greenhouse gas emissions, which can exacerbate climate change.

To ensure the long-term viability of CEA and reduce its environmental impact, sustainable cooling alternatives like Net-house, Root Zone Cooling, and solar power systems should be explored and implemented, as high water and energy consumption evaporative cooling systems compromise sustainability. The international Center for Agricultural Research in the Dray Areas (ICARDA) and National Agricultural Research Systems (NARS) in the Arabian Peninsula have introduced the net-house as a solution to the conventional greenhouse cooling challenge, allowing for 7–9 months of operation in the region. Furthermore, a Ph.D. study supported by ICARDA in Oman demonstrated that the use of root zone cooling (RZC) in the greenhouse enhances crop yield and water productivity. Additionally, ICARDA collaborated with MIT and JANN Irrigation to develop an ultra-low pressure irrigation system that utilizes Ultra Low Energy Drippers (ULED), which provide low-cost, solar-powered drip irrigation solutions [5].

This study aimed to combine five technologies—closed soilless production system, net house, ultra-low pressure irrigation system, root zone area cooling, and low-cost solar energy—to investigate the possibility of improving cucumber crop productivity and extending the production period during the summer months (June to August) in the net house.

This section provides an exploration of various technologies integrated into a solar energy-powered net house system, which were collectively tested in this study. It includes analyses of five key technologies: net house, root zone cooling (RZC), closed soilless production systems, ultra-low-energy drip (ULED) irrigation, and AC/DC hybrid solar energy systems. These technologies are examined individually for their specific roles and benefits. However, their integration as a cohesive package aims to optimize agricultural production in arid regions like the UAE and Oman.

Evaporative Cooling Versus Net Housing in Desert Farming SystemsIn desert regions with mild winters, net houses can sustain production for 7–9 months a year, typically from September to April. However, coverings like polyethylene plastic or polycarbonate on greenhouses can increase interior temperatures, necessitating cooling systems even in optimal external conditions. Single-span Quonset greenhouses covered with 200 μm thick polyethylene films are common in these regions [6] due to their simple evaporative cooling systems. However, these greenhouses and cooling systems, often imported from cooler, more humid countries, face challenges in the Arabian Peninsula’s climate. High relative humidity, particularly in coastal areas, significantly reduces the efficiency of evaporative cooling systems [7], which cannot cool below the wet-bulb temperature [8].

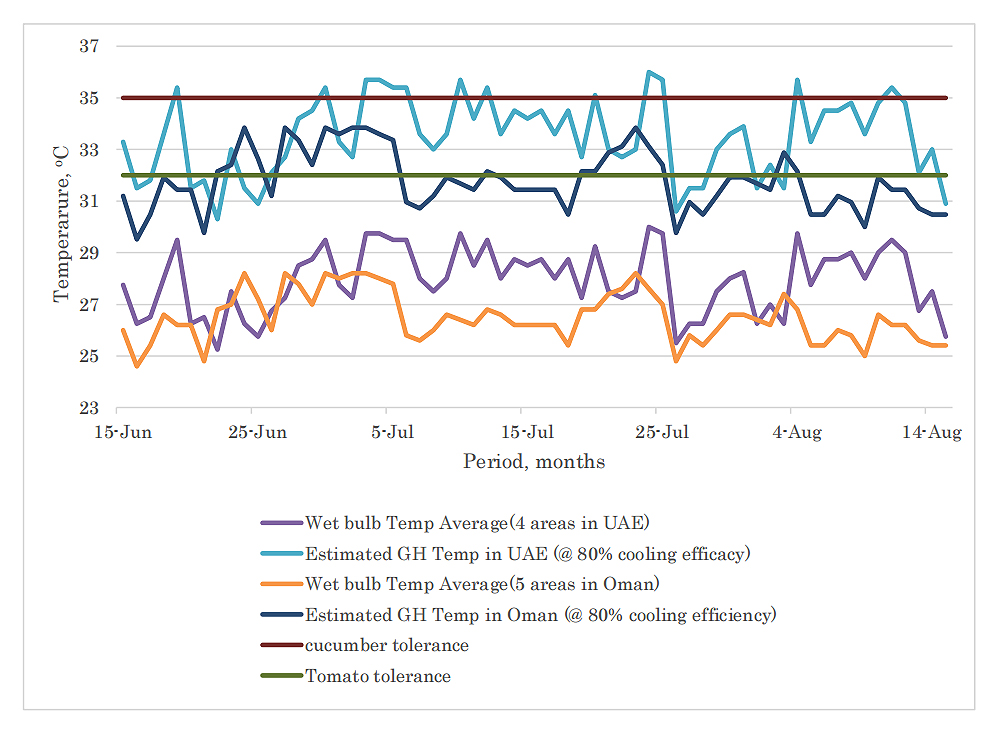

Figure 1 shows the average daily wet-bulb temperature in the UAE (Abu Dhabi, Dubai, Fujairah, and Al Ain) and Oman (Semail, Seeb, Al Merat, Muscat, and Ibra) from 15 June to 15 August 2022, this study duration, based on [9]. The estimated greenhouse temperature, considering an 80% pad efficiency, often exceeds 30 ℃, making it difficult for crops to thrive. In the UAE, temperatures surpass 32 ℃ on 80% of days, compared to 40% in Oman. The UAE generally experiences higher temperatures than Oman, with temperatures exceeding 35 ℃ on 20% of the days.

Tomatoes and cucumbers struggle in such high temperatures. Cucumbers grow best between 20–30 ℃ and exhibit abnormal growth above 35 ℃ [10,11]. Tomatoes can withstand brief high temperatures but suffer from flower and fruit drop if temperatures exceed 32 ℃ during the day or 22 ℃ at night [12]. Local growers often suspend operations during high temperatures, particularly in the UAE, due to reduced market prices from increased imports.

Evaporative cooling systems also consume significant amounts of scarce resources like water and energy, making them less sustainable. In practical terms, pad and fan systems function for approximately 9–10 months per year in these regions, consuming significant quantities of water and energy. When compared to net houses, which operate for 7–9 months without necessitating any water or energy for cooling, these greenhouse structures covered with polycarbonate or polyethylene sheets, designed for cooler areas, are less desirable. They require evaporative cooling for the majority of the year, making them less energy and water-efficient, and potentially less sustainable and cost-effective in these specific climatic conditions.

In contrast, net houses, which provide shade and ventilation while protecting plants from direct sunlight, wind, and pests, are a viable alternative. Net houses can successfully support the production of high-value cash crops for 7–9 months a year. By creating a physical barrier using nets and screens, net houses hinder insect pests from entering the production environment, reducing the need for agrochemicals [13]. Studies by ICARDA and NARS since 2004 have demonstrated that net houses are a viable alternative to cooled greenhouses in the region, with comparable yields and significant water and electricity savings [14].

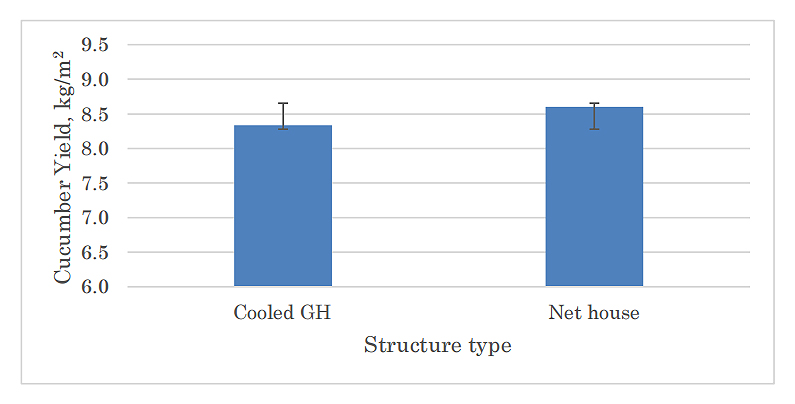

In 2004, ICARDA and NARS in the Arabian Peninsula began studying net houses as an alternative to cooled greenhouses to address the challenges of greenhouse cooling. This was the first study of its kind in Oman, although some activities were carried out in Qatar in the late 90s. In 2008, net houses were introduced to the region, with NARS in the UAE subsidizing 50% of the establishment cost. Figure 2 shows the comparison of cucumber production in net houses versus cooled greenhouses in the UAE from September to December 2012 [15]. The study showed no significant difference in yield between net houses and cooled greenhouses. However, net houses saved a considerable amount of water and electricity for the cooling system [15].

ICARDA’s studies indicate that net houses are less expensive to construct and operate than cooled greenhouses, requiring less energy for cooling. They are also easier to maintain and repair. Additionally, net houses are suitable for a variety of crops, including vegetables, fruits, and ornamental plants. However, they have limitations such as inadequate ventilation in high humidity areas and insufficient protection from severe weather events like hailstorms. Choosing between net houses and cooled greenhouses depends on specific environmental conditions and targeted crops [16]. A temporary polycarbonate cover can extend the system's use to frost-prone mild winter regions, but extreme humidity in coastal areas may hinder its adoption.

Figure 1. Average daily wet-bulb Temp in UAE (Abu Dhabi, Dubai, Fujairah and Al Ain) and Oman (Semail, Seeb, Al Merat, Muscat, and Ibra), between 15 June to 15 August 2022 and estimated greenhouse temperatures based on 80% efficiency of evaporative cooling system [9].

Figure 1. Average daily wet-bulb Temp in UAE (Abu Dhabi, Dubai, Fujairah and Al Ain) and Oman (Semail, Seeb, Al Merat, Muscat, and Ibra), between 15 June to 15 August 2022 and estimated greenhouse temperatures based on 80% efficiency of evaporative cooling system [9].

Figure 2. Comparing cucumber production in 14 private farmers in Net-house VS. Cooled GH in UAE (September to December 2012) [15].

Figure 2. Comparing cucumber production in 14 private farmers in Net-house VS. Cooled GH in UAE (September to December 2012) [15].

Root Zone Cooling (RZC) helps extend crop production periods in net houses by maintaining optimal root zone temperatures, even in hot weather [17]. Various studies confirm that RZC improves yield and quality in hydroponic systems, especially for tomatoes. Kawasaki and his colleagues found that RZC enhances root and shoot growth, nutrient uptake, and root activity, resulting in better plant health and yield. Root cooling-maintained temperatures around 24.7 ℃, boosting root growth and nutrient absorption through increased root IAA levels and root xylem development [18].

In another study on tomatoes, maintaining root temperature at around 25 ℃ increased photosynthesis, stomatal conductance, and shoot growth, even under high air temperatures [19]. Root cooling also counteracts the adverse effects of cool air temperatures during nighttime, enhancing overall yield [20].

Similar benefits were observed for cucumbers. Moon and his colleagues showed that RZC increased cucumber yield and root growth under high air temperatures. Cucumbers grown in a plastic house with cooled root zones exhibited higher yields compared to non-cooled root zones, demonstrating the effectiveness of RZC in mitigating heat stress [21].

Closed Soilless Production SystemA soilless closed production system, which uses mineral nutrient solutions in water instead of soil, allows precise control over plant growing conditions, maximizing yield and quality. This system is particularly beneficial in arid regions with poor soil quality, as it recirculates water and nutrients, reducing waste and increasing efficiency [14].

ICARDA and NARS have developed and promoted soilless production systems in the Arabian Peninsula since the late 1990s, achieving high yields and water productivity. For instance, cucumber production reached 17.3 kg/m² in Oman, and water productivity for tomatoes in the UAE reached 48 kg/m³ under soilless culture compared to 7 kg/m³ under traditional soil systems [22]. In Saudi Arabia, water productivity for tomato crops averaged about 40 kg/m³ under soilless culture versus about 9 kg/m³ under soil systems.

Closed soilless systems are ideal for implementing RZC, as the circulating nutrient-rich water can be cooled to manage root zone temperatures, improving plant health and yield while conserving resources. By adjusting the temperature of the circulating water, growers can directly influence the root zone temperature, thus managing the potential stress from supraoptimal temperatures. This not only addresses heat stress issues but also leads to resource conservation, as the closed system allows for water and nutrient recirculation, reducing waste and enhancing overall system efficiency.

Ultra-Low-Energy Drip IrrigationUltra-Low Energy Drip (ULED) Irrigation systems, designed to operate at low pressures, reduce pumping energy by 80% and facilitate low-cost solar-powered drip irrigation [5]. ULEDs use pressure-compensating designs and labyrinth pathways to deliver a constant flow rate under varying pressures, enhancing irrigation efficiency and reducing water and energy usage [23,24].

The ULEDs utilized in this research feature a pressure compensating design that allows them to deliver a constant flow rate over a wide range of inlet pressures. This is achieved by a flexible diaphragm within the dripper that can expand or contract in response to changing inlet pressures. This design maximizes irrigation efficiency, minimizes water and energy usage, and improves plant health and growth. These emitters were developed through a joint project between ICARDA and the Massachusetts Institute of Technology (MIT) [25].

AC/DC Hybrid Solar EnergyThe AC/DC hybrid solar energy system combines on-grid and off-grid solar energy, prioritizing solar power and using grid power when necessary. This system is effective for RZC, as irrigation stops at night, reducing establishment costs and enhancing sustainability by minimizing fossil fuel reliance and carbon footprint. The on-grid AC/DC solar chiller used for water cooling in this study was designed mainly to work during the daytime using DC power. The system can use solar power and the grid, where solar power is prioritized. When solar power is insufficient, the dual PV MPPT tracking system automatically runs by grid power (AC), providing an uninterrupted supply of power for cooling. This system is well-suited for RZC systems as irrigation stops at night, and water cooling is not required, reducing establishment costs. The use of solar energy-powered ultra-low-pressure drippers further enhances the sustainability of the system, reducing reliance on fossil fuels and minimizing the carbon footprint.

This study aimed to investigate the potential of solar-powered root zone cooling as a means of extending the production period of cucumber crops grown in net houses.

In addition to exploring innovative and sustainable ways to enhance crop yield, the study also aimed to evaluate the effectiveness and cost-benefit of solar powered irrigation system with ULED and cooling the nutrient solution in net houses during the summer months (June-August) using hybrid solar energy in Arabian Peninsula.

The Specific objectives include:

1.

2.

3.

4.

The research activity was caried out simultaneously in the Dhaid Agricultural Research Center (ARC)UAE and Rumais ARC in Oman.

In both sites, the study was conducted in a net house (Net Flex insect proof net cover, Koria) measuring 240 m2, using four varieties of cucumber crops: IZZ F1, Qaisar F1, Nassem F1, and Sultan F1. The seeds were planted on May 15th, 2022, and transplanted on June 1st in the net house in a closed hydroponics production system, using a completely randomized design (CRD) with perlite-filled polystyrene pots (23 × 23 × 20 cm). Each plot consisted of 25 pots, each containing two plants, resulting in a total of 50 plants per plot, with a plot size of 7.5 m2 (1.2 m × 6.25 m).

The irrigation and fertigation system benefited from an intelliDose (Autogrow, New Zealand) system, an automatic irrigation, pH and EC controller and dozer. Solar power for the irrigation system was provided by a 350 W panel, two 33 Ah solar batteries and 30 A charge controller. This system provided 1.75 kW h energy daily to powerup a 450 W VDC submersible pump and 24 VAC/DC intellidose.

The irrigation system also used Ultra Low Energy Drippers 8 L/h (Jann Irrigation, India), as well as an AD/DC hybrid solar root zone cooling system. The 1.5-ton root zone system (SOLARGREEN, China) used 5 panels of 350W each. Additional insect-proof netting was added to provide shading (Figures 3 and 4).

In both location data collection conducted implemented by similar equipment’s. Data collection included yield using a digital balance (A&D Company, USA, 1~150 kg, ±0.05 kg), water consumption using flow meter (B Meter CPR-M3-I, 2.5 m3/h, ±0.05 L), fertilizer usage, and maximum/minimum temperature inside the net house using a Digital thermos-hygrometer (TFA Dostmann, −10 to 60 ℃, 0 to 99% rH) as well as the electricity consumption of the AC/DC hybrid solar system using a single phase current meter (beMatik, Current electricity meter single phase alternating 20 A 230 V 50 Hz max 80 A black plastic, ±0.5 kW h). All statistics analysis were conducted by IBM SPSS software version 26 (version number 26.0, IBM, Chicago, Illinois, USA) with a significance level set at α = 0.05.

To ensure equal water distribution for all cultivated plants, we conducted a uniformity test on the irrigation system. This test assessed the discharge rates of the emitters within the net house. The results demonstrated a uniformity coefficient (CU) of 90%, confirming that the irrigation system distributes water evenly across all cultivation areas [26]. To further ensure the uniformity and efficiency of the irrigation system, water temperature was measured at the beginning and the end of the irrigation line discharged from the drippers. These measurements were conducted to assess any potential variations in water temperature that could affect plant growth. The data indicated that the difference in water temperature between the beginning and end of the irrigation line was not significant (p < 0.05). This minimal variation in temperature ensures that all plants receive water at a consistent temperature, further contributing to the uniform growing conditions within the net house.

The results of the study showed that, in both locations, the crops remained in production throughout the entire summer season. In the UAE, the first harvest occurred on May 26th, 2022, and production continued until August 10th, 2022, with a total of nine harvests and a production yield of 3.3 kg/m2. In Oman, where the study run independently by local researchers, 15 harvests were reported, and the yield reached 8.3 kg/m2.

Notably, no significant differences were observed between cucumber varieties in terms of fruit number and yield in both locations at a 95% level of significance. Figures 5 and 6. Illustrates the average yield (kg/m2/harvest) in UAE and Oman respectively during the study period.

The study also recorded the ambient temperature during the production period in both locations. In the UAE, the maximum average daily temperature during the production period ranged between 38 ℃ and 42 ℃, while in Oman, it ranged from 34 ℃ to 37 ℃ (Figure 7). It is noteworthy that in both locations, crop production under net houses at private farms outside research stations typically ceases by the end of April or early May due to the high temperatures and associated heat stress that negatively impact crop yield.

The production in UAE significantly drops after 40 ℃ while in Oman, where the average max daily temperature never pass 37 ℃, production was significantly higher. This is in line with Nkansah study which presented before on Tomato.

The maximum average daily temperature during the production period (Week 6 to 12) in each location was compared using a t-test, which revealed a significant difference (p < 0.000) between the two locations (Figure 8). Oman also benefits from lower humidity as presented in Figure 1.

In our analysis, we employed the Shapiro-Wilk test to examine the normality of the total weekly production across both sites. Our findings reveal a deviation from the normal distribution in the production output within the UAE, as illustrated in Table 1. Consequently, we resorted to the Mann-Whitney U Test to investigate the discrepancy in production between the two locations.

Table 2 presents a comparison of the mean weekly yields, indicating a significantly superior production volume in Oman.

Figure 9 shows the total cost, total income, and net profit per square meter for cucumber production in net houses with hydroponic systems and root zone cooling powered by solar energy in Rumais, Oman, and Dhaid, UAE during June to 10th August 2022. The total production cost, which includes factors such as depreciation of the greenhouse structure, root zone cooling, and irrigation system, amounted to 6.1 and 5.6 US$/m2 in Oman and the UAE, respectively, based on local market rates. Although both locations had similar production costs, Oman achieved significantly higher yields, resulting in a much higher net income per unit area. Notably, Oman's net income was nearly four times that of the UAE.

The boost in yield observed in Oman can predominantly be ascribed to the relatively cooler dry and wet bulb temperatures experienced throughout the production phase. As illustrated in Figure 1, for cucumber, the optimal growth temperature ranges between 20−30 ℃. Any temperature exceeding 35 ℃ can lead to abnormal growth patterns, as per the study conducted by [10]. In comparison, Dhaid experienced an average daily temperature of 42 ℃ during the production period, while Rumais recorded approximately 35 ℃.

However, the implementation of Root Zone Cooling (RZC) in both locations ensured the plants’ survival and consistent production throughout the entirety of the summer season. Despite this, it should be noted that this approach yielded rather slim profits in the United Arab Emirates (UAE).

The study’s findings emphasize the potential benefits of utilizing renewable energy sources like solar-powered root zone cooling to extend the cucumber production season in net houses during hot summer months. By adopting this innovative and sustainable technology, farmers in the region may be able to continue producing crops and generating income during a season when it would have otherwise been difficult to maintain production. These findings are in line with other research activities in the region. For instance, a 2021 study conducted by ICARDA on using solar-powered root zone cooling under net houses for tomato production in the UAE aimed to reduce water and energy consumption while extending the production period to summer. This study used a net-house with solar-powered ultra-low-pressure drippers and root zone cooling instead of evaporative cooling. The combination of these technologies led to an 85% reduction in water consumption and a 90% reduction in energy consumption, with no negative impact on yield quality or quantity, and extended the production period to June [27]. Another study investigated the effect of root-zone temperature on the growth, yield, and nutrient uptake of cucumber (Cucumis sativus L.) plants grown in a closed soilless production system in a greenhouse during the summer period (June-August) over two consecutive years (2016/2017 and 2017/2018). This study used three cooling treatments—22 ℃, 25 ℃, and 28 ℃—and a non-cooled control (33 ℃). Significant differences (p < 0.05) were observed for plant height, leaf number, chlorophyll content, leaf area, fruit number, yield, and fresh and dry matter weight at all cooled root-zone temperatures compared to the control in both years. Plants at a cooled root-zone temperature of 22 ℃ produced the highest number of fruits per square meter and the highest fruit yields, followed by those at 25 ℃ and 28 ℃, demonstrating the positive impact of optimal root-zone temperatures on cucumber production [28].

These results suggest that utilizing sustainable and innovative technologies, such as solar-powered root zone cooling, can be a cost-effective and profitable approach to enhancing crop yields during the summer season.

Nevertheless, it is essential to note that the decision to use and extend the production period of net houses should be based on the specific environmental conditions and crop requirements of the area.

In conclusion, this study provided a detailed examination of Root Zone Cooling (RZC) and hydroponics systems within solar-powered net houses during the challenging summer months in the UAE and Oman. The findings underscore several key points:

1.

2.

3.

4.

5.

Inspiration for Future Use of Data: The data generated from this study provides a foundation for future research and practical applications. Future studies can build on these findings by exploring additional crop varieties, optimizing RZC system designs, and integrating advanced technologies such as AI-based monitoring and control systems. These efforts can lead to the development of more resilient and efficient agricultural systems tailored to specific regional conditions. Furthermore, economic analysis can guide policymakers and investors in making informed decisions to support the adoption of sustainable agricultural practices. Continued research and development will be crucial in refining these techniques and supporting more efficient and sustainable cucumber production in the future.

In summary, the study demonstrated the potential of these technologies to extend the growing season and improve sustainability, despite initial profitability challenges. Continued research and development will further refine these techniques, supporting more efficient and sustainable cucumber production in the future.

The dataset of the study is available from the authors upon reasonable request.

Arash Nejatian: Contributed to research design, supervised and conducted research activities in the UAE, collected data for both locations, and developed the publication.

Muthir Al Rawahy: Contributed to research design, supervised and conducted research, collected data, reported findings in Oman, and led the national team from the Ministry of Agriculture, Fisheries Wealth, and Water Resources.

Abdul Aziz Niane: Contributed to research design and layout, monitored and managed the overall project, and contributed to the development of the publication.

Amal Hassan Al Ahmadi: Participated in research design, data collection and led the national team from the Ministry of Climate Change and Environment, UAE.

Vinay Nangia: Contributed to and participated in research design and irrigation activities.

Boubaker Dhehibi: Contributed to and participated in economic analysis.

The authors declare that they have no conflicts of interest.

We would like also to acknowledge and express our sincere appreciation for the financial support provided by the Arab Fund for Economic and Social Development (AFESD) and the Kuwait Fund for Arab Economic Development (KFAED) towards the APRP project. Their support has been instrumental in the success of this project.

The authors would like to express their gratitude and appreciation to their counterparts in Oman and the UAE for their support and dedication.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

Nejatian A, Al Rawahy M, Niane AA, Al Ahmadi AH, Nangia V, Dhehibi B. Renewable Energy and Net House Integration for Sustainable Cucumber Crop Production in the Arabian Peninsula: Extending Growing Seasons and Reducing Resource Use. J Sustain Res. 2024;6(3):e240038. https://doi.org/10.20900/jsr20240038

Copyright © 2024 Hapres Co., Ltd. Privacy Policy | Terms and Conditions